Machine Capabilities

Our Water jet Machine uses a very high-pressure jet of water to cut through all types of foam to custom shapes and sizes. The water shoots throughout the full thickness of the foam for custom foam packaging and small or large volume quantity orders at 1/16” tolerances.

We also have an abrasive substance mixture of water to cut hard materials such as wood, rubber, metal, or granite. Flat sheets from 1/16” thick to 7” thickness can be stacked and laid on this table and will cut the top view of a specific cut-out.

Size of table: 8ft x 12ft

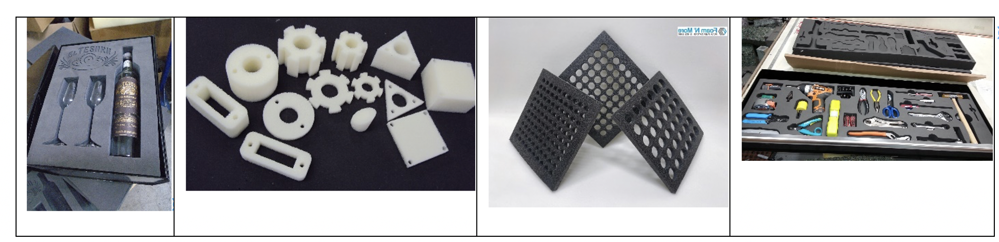

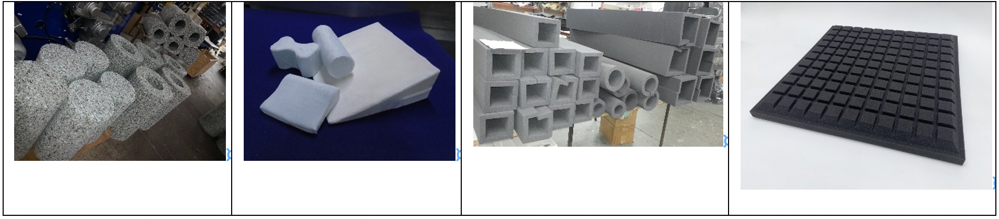

Waterjet cutting photo Examples:

Commonly used for: Custom Case Foam Inserts, volume cutting for packaging and protecting, round mattresses, Letters and Art and Crafts Projects, polystyrene decorations.

This machine uses a jet stream of water which is forced through a tiny nozzle at a high pressure to perform precision cutting and piercing up to accuracies of ± .005 leaving smooth, extremely accurate edges.

We have both types of waterjet cutting, including:

- Pure waterjet - This process only uses water as a cutting tool. It is used for cutting softer materials such as gaskets, foam, food, paper, carpet, and plastic.

- Abrasive waterjet - This process adds a mix of abrasive materials to the water for more accurate cuts on materials such as metal, ceramic, stone, wood, and glass.

Our Automatic Vertical Ban Foam Saw: Once the thickness is cut, we use this machine to slice foam down to the correct widths and lengths. If the widths and lengths of the foam are small enough, this machine can also cut the thickness too.

Our Automatic Vertical Ban Foam Saw: Once the thickness is cut, we use this machine to slice foam down to the correct widths and lengths. If the widths and lengths of the foam are small enough, this machine can also cut the thickness too.

Size of table: Cut up to 26” thick x 96” long x 68” wide (29” left of black width x 39” right of blade)

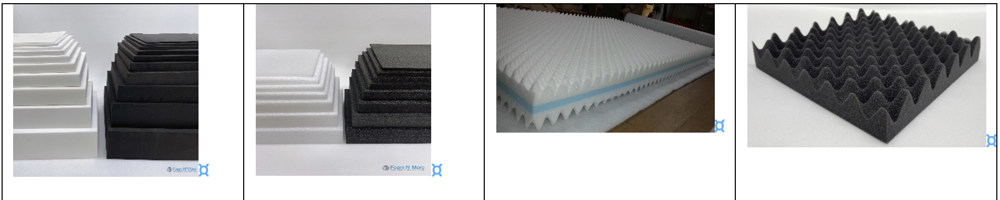

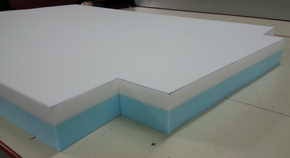

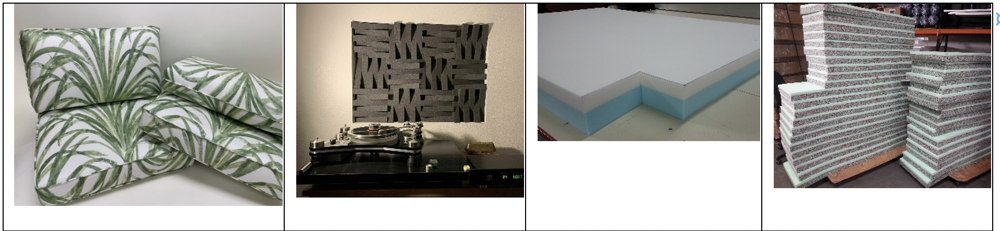

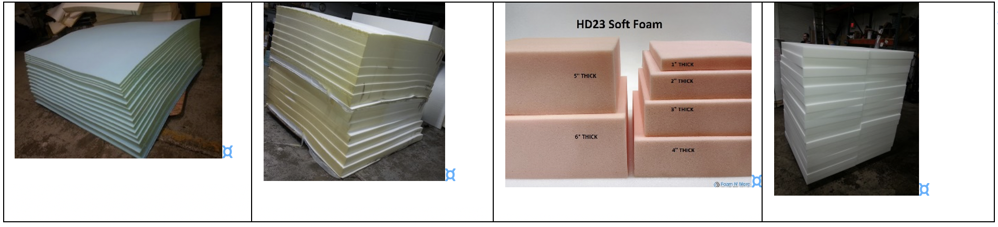

Vertical Foam Saw cutting photo Examples:

Commonly used for: Flat Open and Closed Cell Foam sheets, Acoustic Tiles, Sofa Cushions, Seat Cushions, Open Cell Strips, Closed Cell Foam Cut to Size or strips, and all mattresses sizes.

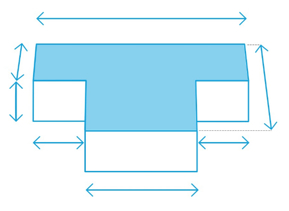

Our CNC Machine will custom cut any 2-D shapes in different densities of open-cell foam in long strips and thicknesses. A full bun is placed on the table and the horizontal saw blade will cut as many pieces as it can get out of the bun. The table can also rotate in different directions to cut out pyramid-shaped acoustic tiles.

CNC contouring cutting is the most typical fabrication technique to produce 2D foam shape products. The contour cutter uses high-speed grinding blades or wire to cut the foam into various shapes, curves, and diameters. Cylinders, or contour shape foam pieces, we use contour foam cutting techniques to cut patterns automatically. Custom contour cut foam allows a user to create intricate shapes in the foam at low tooling costs. Before machinery was built to do this automatically, foam blocks were cut by hand using paper or wood according to a hand-drawn pattern to cut the perimeter of any custom shape.

Our two machines offer great versatility, as one is a vertical machine achieving maximum heights of 44”, and the other is a horizontal machine that can fabricate up to 108” in length, thus ensuring the best yield for your contour cut foam.

Size of table: 7ft x 9ft

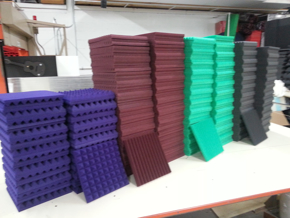

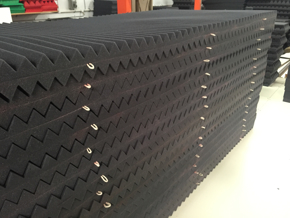

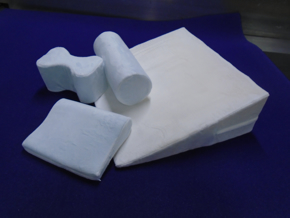

CNC Machine Saw cutting photo Examples:

Commonly used for: Arabic arms and seating shapes, acoustic wedge and pyramid foam, bass absorbers, acoustic tiles, pole bumpers, medical foam shapes, round bolsters, back bolsters, wedge shapes, fillers, etc.

Our Horizontal Foam Slitter will cut any type of Open Cell Foam to its correct thickness. A full bun is placed on the table and this table moves so that the horizontal saw blade can cut quickly through to the table in pieces as thin as 1/4” or thicker.

Size of table: 7ft x 9ft

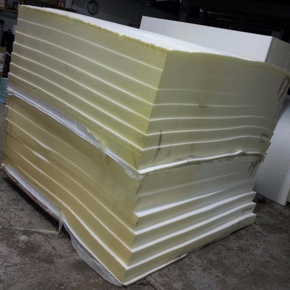

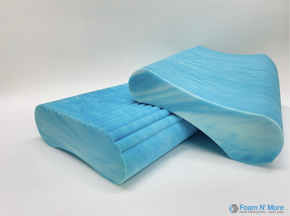

Foam cutting photo Examples:

Commonly used for: Most types of high-density open-cell foam for upholstery, packaging, memory foam, latex foam, and rebounded foam.

This Machine comes with 2 rollers:

- The first Roller is called a Foam Splitter which can split the thickness of closed-cell foam into flat sheets from 1lbs density to 6lbs density and anywhere from 1/16” thick to 4” thickness.

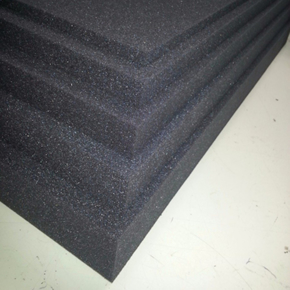

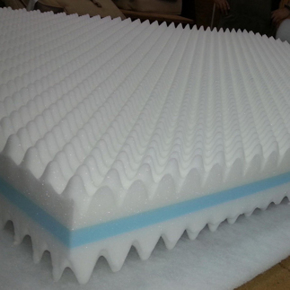

- The second roller is called a Convolution roller machine (only used for Open Cell Foam). The roller is designed in a convoluted egg-crate shape and can slice a flat 3” thick open cell foam sheet down to 2 sheets of 2-1/2” thick convoluted egg-crate shapes (3″ thick when you interlock them together). This roller can be adjusted to cut convoluted egg crate sheets in different heights and picks.

Convoluted Cutting Processes

Convoluted cutting is similar to skiving cutting, which cuts one sheet into two half pieces and can produce ridged designs like peaks and valleys. The convoluted cutting process begins with a large flat foam sheet that is pressed by a long roller as a blade slices it. The pressure from the roller and the special cutting blade results in custom patterns with valleys and peaks.

Convoluted foam is very common in applications like:

• cameras

• instruments

We can use this process on anti-static, and open-cell.

Size of table: 7ft x 9ft

Foam cutting photo examples: