Waterjetting; The Cutting-Edge for Perfect Foam Solutions

At Foam N' More, we're committed to delivering exceptional foam products tailored to your unique needs. Whether you're searching for a custom foam mattress, protective foam for playgrounds, or specialized packaging solutions, precision is key. That’s why we use state-of-the-art water jetting technology to cut our foam with unparalleled accuracy.

What is Waterjetting?

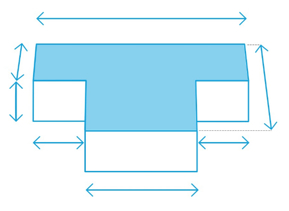

Water jetting is a cutting-edge technique that uses a high-pressure stream of water, often mixed with abrasive materials, to slice through various materials, including foam. The process is both precise and versatile, allowing us to achieve intricate shapes and dimensions with ease.

The Advantages of Waterjetting for Foam Cutting

1. Precision and Accuracy

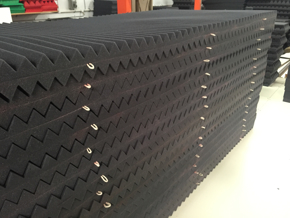

One of the standout benefits of water jetting is its remarkable precision. The technique allows us to cut foam to exact specifications, ensuring a perfect fit for your intended application. Whether you need a foam cushion for a custom mattress or intricate shapes for playground safety, water jetting delivers flawless results every time.

2. Clean Cuts with Minimal Waste

Traditional cutting methods can sometimes produce rough edges or generate excess waste. Waterjetting, on the other hand, creates smooth, clean cuts with minimal waste. This not only enhances the quality of our foam products but also contributes to our commitment to environmental sustainability.

3. Versatility in Material Types

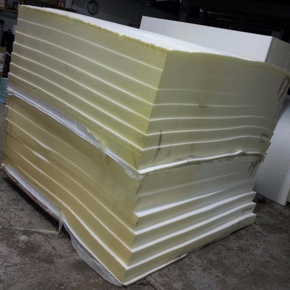

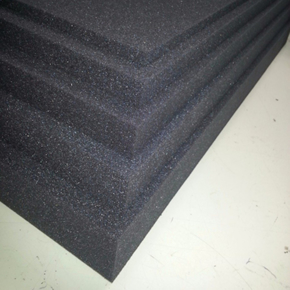

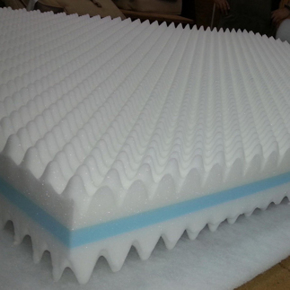

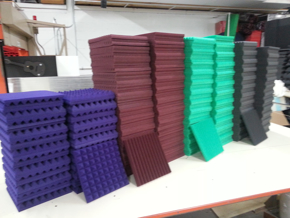

Waterjetting is highly versatile, making it suitable for a wide range of foam types. From soft, cushy materials used in pillows and mattresses to more rigid forms needed for protective applications, water jetting can handle them all. This versatility ensures that we can meet diverse customer needs efficiently.

4. Customization and Flexibility

Our customers often have specific requirements for their foam products, and water jetting enables us to accommodate a broad array of customizations. Whether you need unique shapes, sizes, or designs, our water jetting capabilities provide the flexibility to bring your vision to life.

How Foam N' More Utilizes Waterjetting

At Foam N' More, we employ advanced water jetting technology to craft a wide range of foam products:

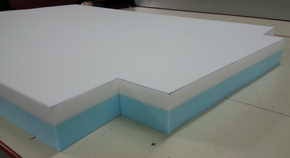

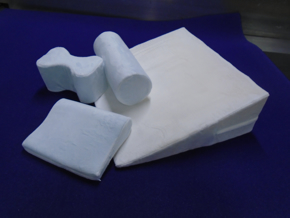

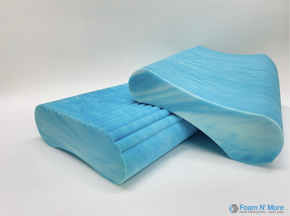

- Mattresses and Pillows: Perfectly cut foam ensures optimal comfort and support.

- Packaging Foam: Tailored cuts protect delicate items during transit.

- Upholstery Foam: Custom shapes and sizes for furniture and other applications.

- Outdoor Foam: Weather-resistant cuts for patio and garden furniture.

- Protective Foam: Shapes designed to safeguard playgrounds and gymnasiums.

- Medical Foam: Precision cuts for medical equipment and patient care.

Experience the Difference

Our commitment to quality and innovation is reflected in our use of water-jetting technology. By leveraging this advanced technique, Foam N' More ensures that every product we deliver meets the highest standards of precision and excellence.

Explore our wide range of standard and custom foam products today, and experience the Foam N' More difference. Whether you're looking for a custom-cut mattress or specialized foam for a unique application, we have the expertise and technology to exceed your expectations.

For more information on our foam-cutting capabilities or to discuss your specific needs, contact us by calling (248) 284-0002 or sending in an online contact form today!