Precision and Power: Foam N More Water Jetting Solutions

picture 2_1000.jpeg)

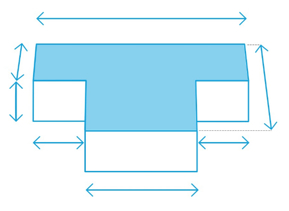

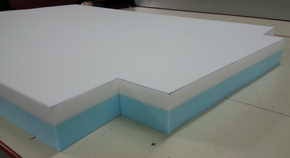

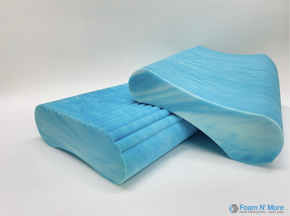

When it comes to cutting, shaping, and processing foam, precision matters — and that’s exactly what Foam N More’s water jetting services provide. Using high-pressure water streams, water jetting allows for clean, accurate, and efficient cutting of foam materials, helping manufacturers, hobbyists, and businesses achieve exact results every time.

What is Water Jetting?

Water jetting is a cutting process that uses a high-pressure stream of water to slice through materials. For foam, this method offers exceptional precision without causing damage, melting, or deformation. Unlike mechanical cutting, water jetting does not generate heat, meaning the foam retains its original properties and structure. This is especially important for delicate or specialized foam products.

Applications of Water Jetting

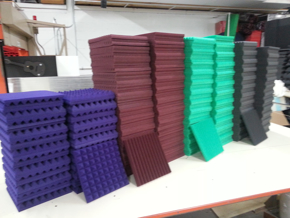

Foam N More’s water jetting capabilities are versatile and ideal for a wide range of applications:

-

Custom Foam Shapes – Create unique shapes for packaging, displays, or décor with high accuracy.

-

Prototyping & Manufacturing – Perfect for producing consistent foam parts for industrial, medical, or commercial products.

-

Signage and Graphics – Cut foam letters, logos, and decorative elements cleanly and efficiently.

-

Art and Craft Projects – Hobbyists and designers can produce intricate shapes and patterns that are impossible with traditional cutting methods.

-

Construction & Insulation – Water jetting allows precise cuts for foam used in building, insulation, or architectural applications.

No matter the size or complexity of your project, water jetting ensures every cut is smooth and precise, reducing waste and saving time.

Benefits of Foam Water Jetting

-

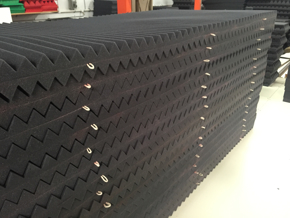

High Precision: Perfect for intricate designs and detailed cuts.

-

Clean Cuts: No fraying, melting, or deformation of foam edges.

-

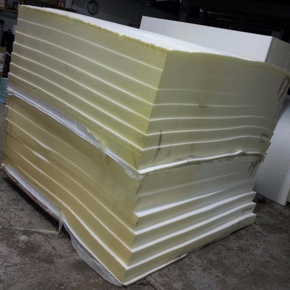

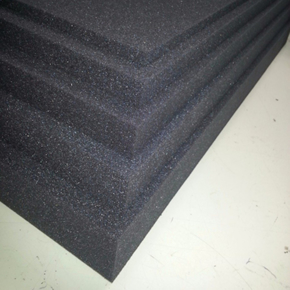

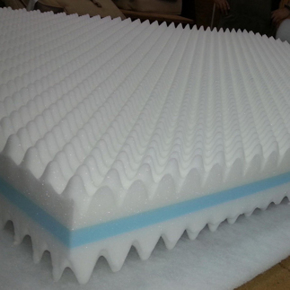

Versatility: Works with a wide variety of foam densities and types.

-

Cost-Effective: Reduces material waste and minimizes the need for rework.

-

Fast Turnaround: Efficient cutting process speeds up production timelines.

-

Eco-Friendly: Uses water rather than chemicals, making it a safe option for the environment.

Why Choose Foam N More

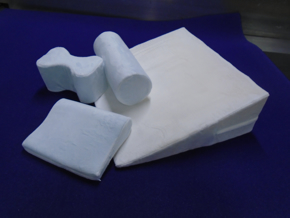

Foam N More combines state-of-the-art water jetting equipment with years of experience in foam fabrication. Our team ensures that every project — whether small, custom orders or large production runs — meets strict quality standards and is delivered on time.

We work with clients across industries, including packaging, manufacturing, signage, and arts & crafts, providing solutions that are tailored to your specific foam requirements.

How to Get Started

If your project requires precision foam cutting, Foam N More makes the process simple. Share your specifications, dimensions, or design files, and our team will handle the rest. We offer guidance on material selection, cutting tolerances, and design optimization to ensure your project meets expectations.

Experience the Foam N More Difference

From one-of-a-kind custom pieces to large-scale manufacturing runs, Foam N More’s water jetting services deliver clean, precise, and efficient foam cutting solutions. Our combination of advanced technology, skilled craftsmanship, and commitment to quality ensures that your foam products are cut exactly as intended — every time.

Discover the versatility and precision of Foam N More water jetting and take your foam projects to the next level.

_1000.jpeg)