Comparing Memory Foam and Latex Foam

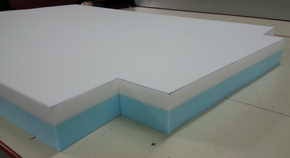

When looking for foam for your project you may wonder – what’s the difference between memory foam and latex foam? The first difference is between the two products’ ability to “bounce back.” Latex is more elastic than memory foam, making it useful in mattresses, pillows, cushions, and furniture. On the other hand, memory foam has less elasticity so it doesn’t bounce back as well. The value of memory foam is in its superior level of cushion, making it one of the most desirable products for mattresses and medical industry uses.

Both latex and memory foam products offer superior comfort, wide availability, and ease of use. They can both be used in nearly anything from furniture to construction – but which one is right for your needs?

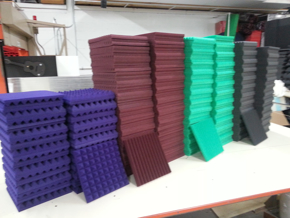

Both products have a large range of sizes, constructions, colors, and densities, so let’s break down how you can use each product effectively.

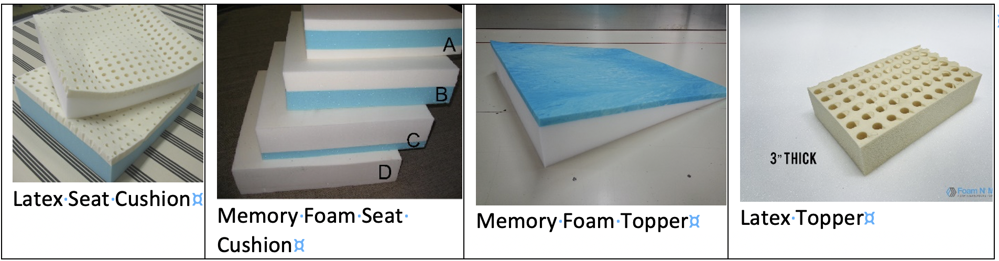

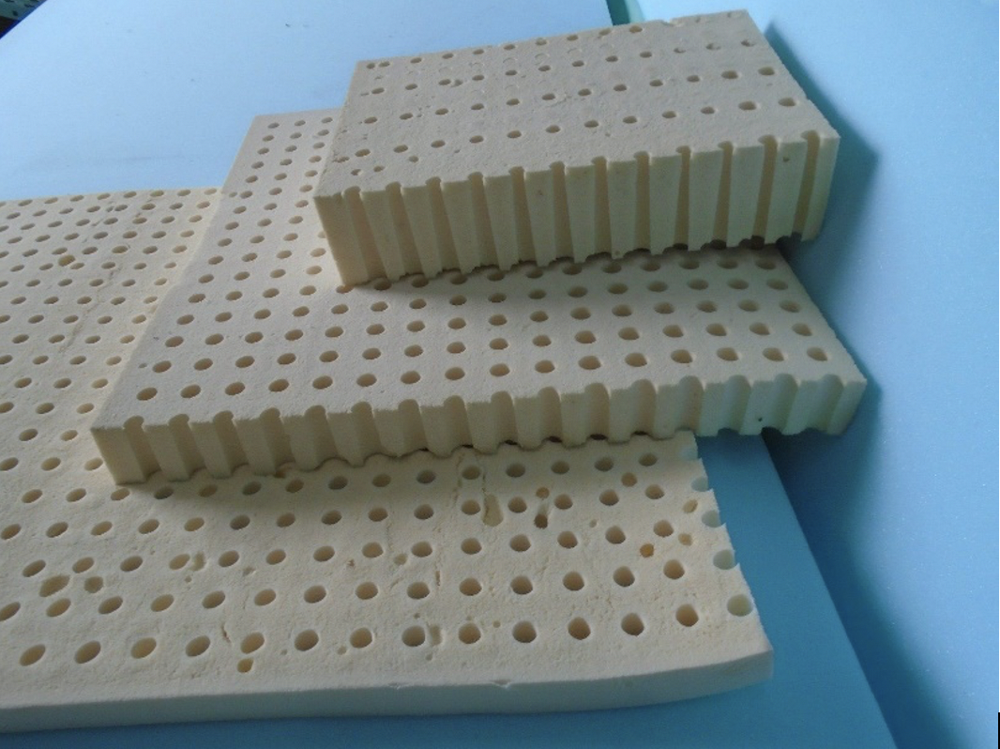

Latex Foam

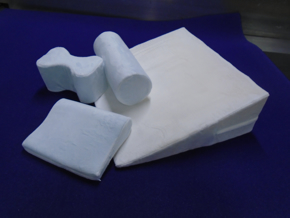

Latex foam can come in many different types and densities to give it a wide range of properties depending on the various treatments that are applied to it while creating the foam. Almost every form of latex foam offers excellent energy absorption, thermal conductivity, and compression. These benefits make it perfect for commercial applications like upholstery, mattresses, cushions, and medical uses. Latex is the firmer option, whereas memory foam is a lower density.

Latex Manufacturing Processes

The terms “Talalay” and “Dunlop” refer to the two different methods of manufacturing Latex Rubber for sleep products. The Dunlop process was developed in 1929. It was the first process created to produce latex material for bedding. Dunlop Latex is what Foam N’ More supplies.

Both Talalay and Dunlop processes start with a formula mixture of liquid latex. These formulas can be any of the following:

100% natural latex rubber (harvested from rubber tree plants)

100% synthetic latex rubber (a man-made molecular copy of natural latex rubber)

Blended natural and synthetic latex rubbers (specific blend ratios are proprietary)

Note: there are small amounts of other materials required for processing liquid latex into solid form which is necessary for all latex production. (ingredients & amounts are proprietary)

Dunlop Latex production process

- Liquid latex formula is poured onto a long conveyor belt.

- Liquid latex is slowly heated until it “gels” into a permanent solid form.

- Cooled solid latex is removed from a conveyor belt.

- Liquid latex formulation is poured into a mold and sealed closed.

- A vacuum is created to disperse liquid latex throughout the mold.

- Liquid latex is flash frozen.

- Frozen latex is flash heated until “gels” into a permanent solid form.

- Cooled solid latex is removed from the mold.

Talalay Latex production process

Differences between Talalay Latex and Dunlop Latex

The Talalay process for producing latex is significantly more complex and costly. It results in softer, more buoyant, and luxurious finished products. Talalay is produced using only 100% Natural or Blended formulations to meet optimum quality standards.

The difference in processing comes with the two additional steps that occur in the Talalay process - #2 Vaccum & #3 Freeze.

#2 Vaccum – This step allows any amount of latex to be evenly distributed throughout the mold creating precise and varied firmness with the finished latex. The more liquid latex that’s poured into the mold, the firmer the resulting solid latex. Therefore, if less liquid latex is used, a softer more supple piece of latex results.

This differs from Dunlop in that the Dunlop process has very little ability to vary the firmness or feel of the finished solid product while maintaining structural integrity. The liquid formula is poured onto a belt and you get the same, dense piece of latex every time. The only way to soften the feel of Dunlop latex is to add fillers into the liquid latex formula. This is not recommended as it results in solid latex that is flaky and breaks down quickly.

#3 Flash Freeze – This step provides Talalay with its uniquely consistent characteristic. Liquid Latex is a suspension of rubber particles in water, like a shaken snow globe. Flash freezing prevents the latex particles from settling to the bottom while the latex gels into a solid product. This means that the resulting piece of solid Talalay latex has the same consistent feel from top to bottom.

This differs from Dunlop because the Dunlop process does not utilize a freeze step. Therefore, the rubber particles settle to the bottom while the liquid latex is gelling to a solid form, resulting in a variation of feel from top to bottom. If Dunlop latex is used as the bottom layer of a mattress, this will not affect the comfort of your mattress. However, if Dunlop latex is used in pillows or the top layer of a mattress, the difference will be noticeable.

Takeaways

While the Talalay process is more expensive and takes four times longer than the Dunlop process due to the two additional steps, these steps improve the finished product’s consistency, quality, and feel.

To simplify it with an analogy, Talalay latex is more like a chocolate soufflé, while Dunlop Latex is more like a brownie. While the soufflé is more expensive, it is buoyant, airy, and complex, whereas the brownie is less expensive, more dense and flat, but still satisfying.

Memory Foam

Also known as temper foam, memory foam was developed under NASA during the 1970s. It was designed to improve seat cushioning and crash protection for airline pilots and passengers. Memory foam has many applications, both commercial and residential. In addition to mattresses, pillows, and shoes, memory foam is also a favorite in the medical industry. It is the top choice for seat, bed, and wheelchair cushions. Memory foam has a comforting nature and thereby provides more comfort and support to pressure points like hips, arms, and legs. It does so by cradling the body while allowing more airflow than most open-cell foams.

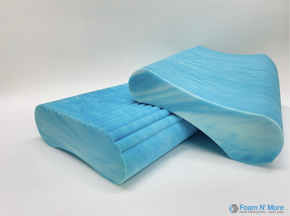

Memory foam has been scientifically tested for long-lasting durability and comfort for the user to give them enhanced pressure relief compared to other forms. Our memory foam is a 4lbs density and is mixed with the Memory Gel Swirl, a technology created by using Variable Pressure Foaming. Our innovative dual-wave gel technology reinforces enveloping open-cell breathable Visco foam with gel-infused waves to provide enhanced support along with cradling comfort that will not cause you to overheat at night.

This gel memory foam is the leading type of foam innovation in the Bedding, Industrial, Home & Office, Furniture, Healthcare, and Transportation markets. Variable Pressure Foaming is a process that uses enclosed chambers to maintain atmospheric conditions. By doing this, it delivers consistently perfectly formed high-quality products. Memory Gel Swirl is created without using mercury, phthalates, formaldehyde, ozone depleters, and is low on VOC emissions – all together making it CertiPUR-US certified. This type of blend ensures consistent high-quality and environmentally friendly foam that protects our environment with virtually zero emissions, eliminating CFCs and other blowing agents that can be harmful.

|

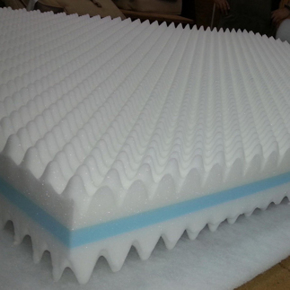

Gel Memory Foam

|

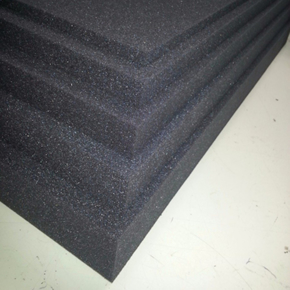

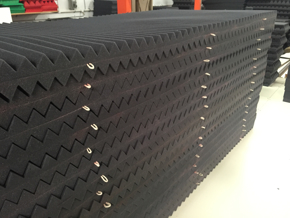

Dunlop Latex Foam

|

The memory foam vs latex foam debate may wage on, but we offer answers for all your project needs. In conclusion, latex foam is a firmer choice than gel memory foam, while the memory foam offers a greater level of comfort in most applications. We offer a wide variety of foams to meet any of your specific project needs. If you have a question about what foam works best for your project, call one of our agents today for a custom expert consultation.

I'm looking to replace the foam on my medical examination table. I think, froom your descriptions above that the lates foam is the best option, but I'd appreciate a call from someone knowledgeable on the subject. Hoping to avoid ordering the wrong thing.

Thanks, in advance.

Perry M. Perretz

203-544-9090