Precision and Versatility: Waterjet-Cut Custom Foam Products by Foam N' More

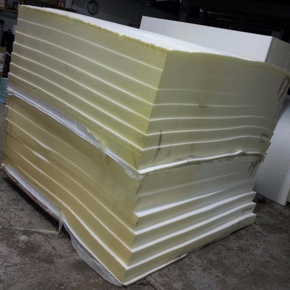

In today's dynamic world of design and innovation, foam has emerged as a remarkable material for various applications. From cushioning furniture and mattresses to packaging and insulation, foam plays an indispensable role in our lives. Foam N' More, a leading foam manufacturing company, has taken this versatility to new heights by harnessing the power of waterjet technology to create custom-cut foam products with unparalleled precision and quality. In this blog article, we will delve into the art of waterjet-cut custom foam products and how Foam N' More has revolutionized the industry with this advanced technique.

The Rise of Waterjet Technology in Foam Cutting

Traditionally, foam cutting involved methods like die-cutting, bandsaw cutting, and even manual carving. These techniques were effective to some extent but often led to imprecise cuts, wastage, and limited design possibilities. With the advent of waterjet technology, a cutting-edge solution was introduced to overcome these challenges.

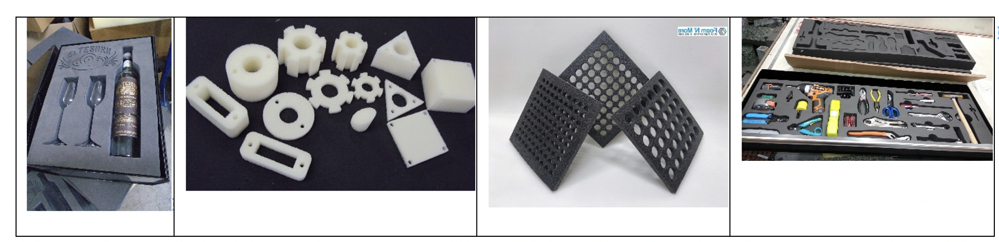

Waterjet cutting involves the use of high-pressure water streams mixed with abrasive particles to slice through foam materials with exceptional precision. This process enables the creation of intricate shapes and designs that were once considered unattainable. The versatility of waterjet cutting allows Foam N' More to cater to various industries, including automotive, aerospace, medical, packaging, and more.

The Art of Waterjet-Cut Custom Foam Products

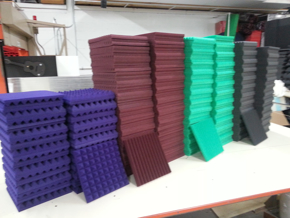

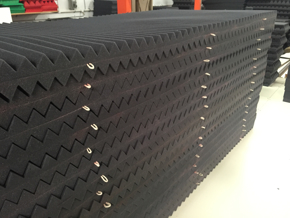

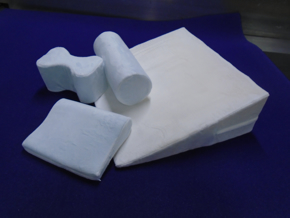

At Foam N' More, waterjet cutting is nothing short of an art form. It begins with our team of skilled designers working closely with clients to understand their specific requirements. Whether it's custom cushions for furniture, acoustic foam panels, or protective inserts for delicate equipment, we take pride in turning our clients' visions into reality.

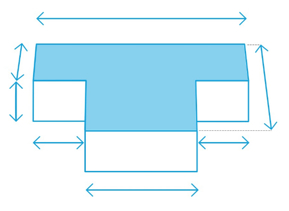

The process starts by digitizing the design or pattern provided by the client. This digital file is then used to program our state-of-the-art waterjet cutting machines. The foam material is placed on the cutting bed, and the water jet is set in motion. The combination of water and abrasives generates a focused and powerful stream that precisely cuts through the foam, creating a flawless product.

Advantages of Waterjet-Cut Custom Foam Products

- Precision: Waterjet cutting offers an impressive level of accuracy, resulting in clean, smooth edges and precise dimensions. This ensures that every foam product matches the exact specifications provided by the client.

- Minimal Material Wastage: Traditional foam cutting methods often lead to significant material wastage due to imprecise cuts. Waterjet cutting, on the other hand, minimizes waste, making it a cost-effective and eco-friendly solution.

- Versatility: The waterjet cutting process allows Foam N' More to create foam products in a wide range of shapes and sizes. Whether it's intricate patterns or complex geometries, waterjet cutting brings design possibilities to new horizons.

- Quick Turnaround: With the use of advanced waterjet technology, Foam N' More can deliver custom foam products in a shorter time frame than traditional cutting methods, without compromising on quality.

Applications of Waterjet-Cut Custom Foam Products

The applications of waterjet-cut custom foam products are virtually limitless. Some common industries that benefit from our services include:

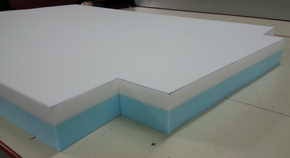

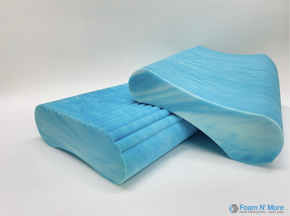

- Furniture: Tailor-made foam cushions for sofas, chairs, and outdoor furniture, ensuring maximum comfort and durability.

- Packaging: Precisely cut foam inserts to protect delicate and valuable items during shipping and transit.

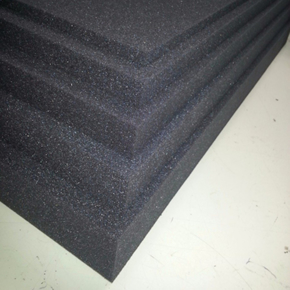

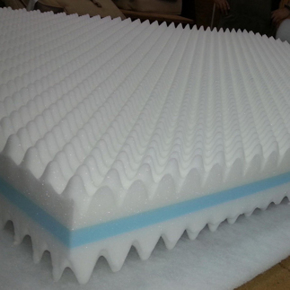

- Acoustics: Acoustic foam panels designed to improve sound quality in recording studios, theaters, and commercial spaces.

- Medical: Custom foam padding for medical equipment, patient positioning, and support.

Custom Cut Foam Products, Any Shape and Size | Foam N’ More

The combination of foam and waterjet technology has ushered in a new era of precision and creativity. Foam N' More continues to push the boundaries of innovation, providing clients with top-notch waterjet-cut custom foam products that cater to a diverse range of industries. Whether you need custom cushions, packaging inserts, or acoustic panels, Foam N' More's cutting-edge waterjet technology ensures that your vision comes to life with unmatched precision and quality.

Contact us today by calling (248) 284-0002 or filling out an online contact form!